Tel/wechat/whatsapp : +86 13758983507

Email : info@homeindoor.cn

Flush wood doors are a popular choice in modern architecture and interior design due to their clean appearance, durability, and affordability. They offer a smooth and sleek surface that blends well with contemporary and traditional decor alike. In this article, we'll explore what a flush wood door is, how it's constructed, its finish options, and the reasons to choose one for your home or commercial space.

A flush wood door is a type of door with a flat, smooth surface, free of any panels, molding, or intricate designs. It is typically made with a wooden frame and covered with plywood, MDF, or veneer sheets on both sides. The simplicity of its design gives it a modern, minimalist look that suits a variety of interiors.

Flush doors are widely used in residential, commercial, and institutional buildings due to their clean appearance and practicality.

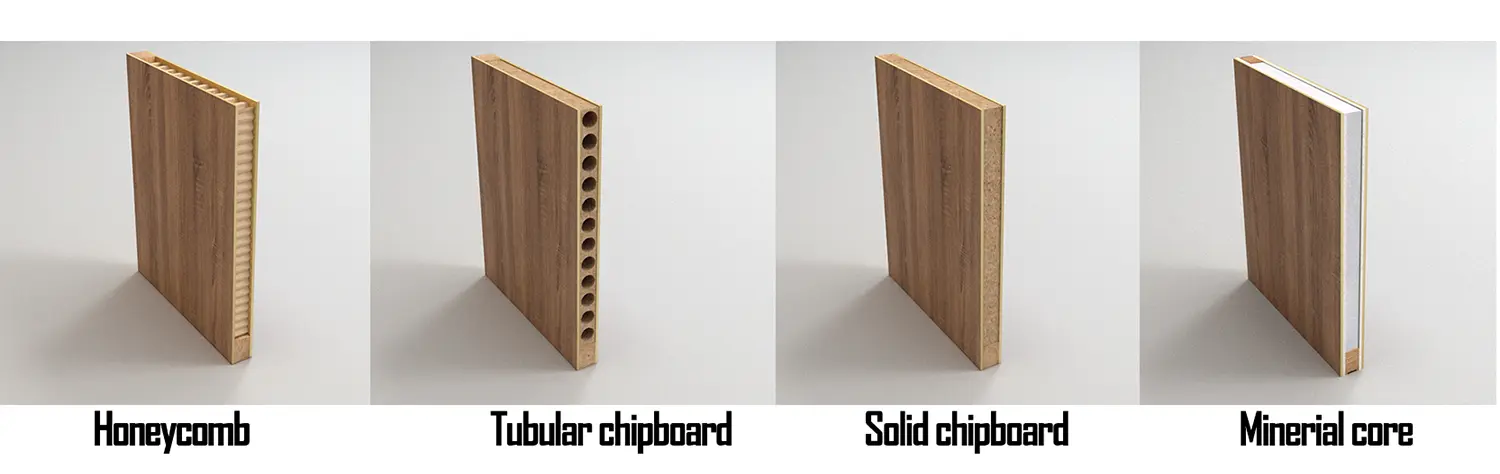

Flush wood doors come in two main types based on their core construction:

| No. | Core Type | Description |

|---|---|---|

| 1. | Solid Core | Made from solid wood or particleboard; offers durability and moderate insulation. |

| 2. | Solid Mineral Core | Constructed from fire-resistant mineral materials; ideal for fire-rated doors. |

| 3. | PU Foam Core | Lightweight polyurethane foam; provides thermal insulation and easy handling. |

| 4. | Acoustic Isolation Core | Made with sound-dampening materials; enhances soundproofing for quiet spaces. |

| 5. | Hollow Core | Features a honeycomb or grid structure inside; lightweight and economical. |

| Component | Description |

|---|---|

| Core | Either solid or hollow, providing the door's structural stability. |

| Stiles & Rails | Wooden frame surrounding the core to strengthen the door and support hardware. |

| Face Material | Sheets of plywood, MDF, laminate, or decorative veneer applied to both sides. |

| Lipping (Optional) | Hardwood strips on edges for added strength and improved screw-holding. |

Flush wood doors can be finished in various ways, depending on the aesthetic and functional requirements:

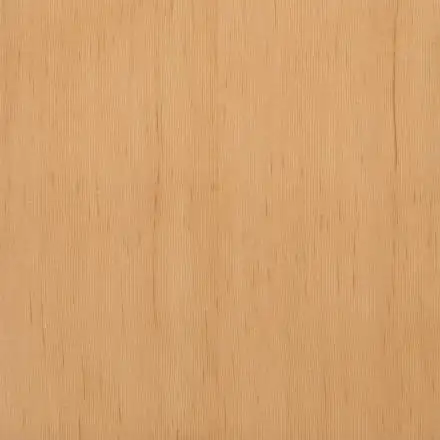

Thin slices of natural wood like teak, oak, or mahogany.

Gives a rich, elegant wood grain appearance.

Can be polished or stained.

Decorative synthetic sheet glued to the surface.

Available in various colors, patterns, and textures.

Scratch-resistant and easy to clean.

Painted in any desired color.

Suitable for matching custom interior palettes.

Melamine is a hard resin-coated paper pressed onto MDF or particleboard under heat and pressure.

Offers a durable, moisture-resistant, and low-maintenance surface.

Available in a variety of solid colors, woodgrains, and textures.

Ideal for commercial applications, kitchens, and high-humidity areas.

There are several compelling reasons to choose a flush wood door:

Sleek and modern design enhances contemporary interiors.

Customizable with various finishes and colors.

More affordable than solid wood or paneled doors.

Available in both budget and premium variants.

Hollow core versions are easy to transport and install.

Reduces load on door frames and hinges.

High-quality finishes like laminate resist scratches and stains.

Long lifespan with minimal upkeep.

Suitable for residential, commercial, and institutional use.

Can be used for internal and semi-external doorways.

Flush wood doors offer a practical, stylish, and economical solution for a wide range of building projects. With their simple design and flexible finishing options, they provide both aesthetic value and functional benefits. Whether you're designing a modern office or remodeling your home, flush wood doors can be a reliable and attractive choice.

Optional Veneer & Texture

Optional solid color

Standard packaging is the door around the foam corner and edge protection, the surface of a layer of sponge film, and then put into a cardboard box, wrapped with tape; safe packaging can reduce the damage brought about by scratches and collisions in the handling process on site

After the standard packaging, and then put each door into the wooden box, usually the wooden box is made of plywood board or particle board, the bottom of the wooden box has a base can be forklift truck work; Obviously the wooden box packaging increases the cost, but it also brings a lot of benefits, 1 . Convenient for loading and unloading 2. Avoiding damage to the product from collision during international transport, especially for doors with glass.

This packaging is dedicated to pre-hung doors, especially for the North American market, pre-hung doors can greatly save the installation of labor costs and installation time, but pre-hung packaging volume is twice as large as the standard package, reducing the amount of loading quantity to increase the customer's transportation costs

We have no minimum order quantity and accept orders in any quantity.Whether you need a single door or material for an entire project, we offer affordable product price and shipping to your country

Any size within the maximum size range can be customized,

Of course,We have a wide range of standard colors to choose from, and we can also produce according to the color card provided by the customer.

Of course, we can ! Our profesional designer can provide detailed design drawings to confirm the specifications and materials before production.

You can also download reference drawing on our website

Of course, we can provide different materials, colors, styles, prices of hardware accessories for customers to choose, where you can one-stop shopping for doors and accessories! Most of our hardware is made in china (chinese brand), We can also supply hardware made by international Top brands (such as Häfele, Dorma), or Equivalent China-made hardware