Why Choose Flush Wood Interior Doors?

An In-Depth Guide to the Benefits, Customizations, and Performance of Flush Wood Doors

When selecting interior doors for residential, commercial, or institutional buildings, the balance between aesthetics, performance, cost, and delivery speed is essential. Among the many types available in the market, flush wood interior doors have gained strong popularity due to their minimalistic design, versatile construction, customizable material options, and performance capabilities like fire resistance and soundproofing.

This guide explores why flush wood interior doors are the preferred solution for modern construction and renovation projects, including six key reasons that highlight their material flexibility, economic benefits, quick lead time, size adaptability, rich surface finishes, and high technical performance.

1. Flexible Material Options to Meet Your Budget and Performance Needs

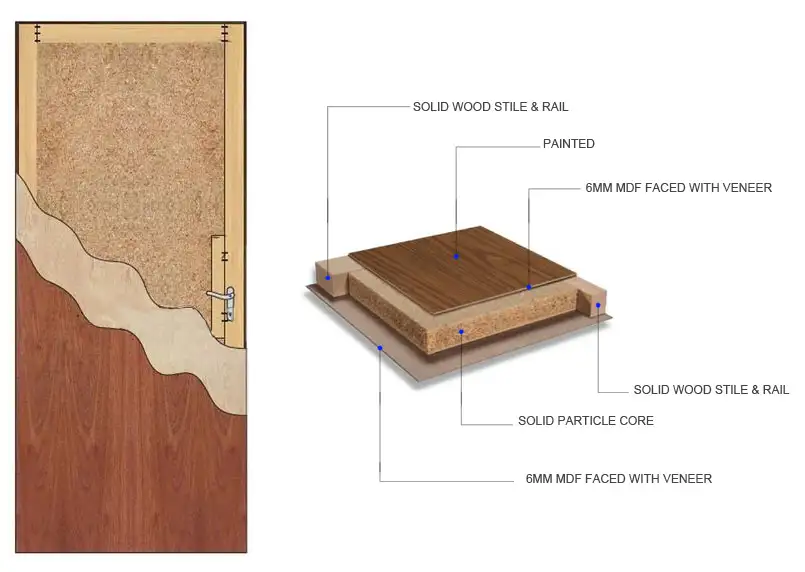

One of the greatest strengths of flush wood interior doors lies in their highly adaptable construction. Unlike traditional stile-and-rail doors, flush doors offer a broad range of material combinations that allow architects, builders, and end-users to customize the door to meet specific budget, design, or performance requirements.

Face Panel Options

The face panel defines the surface appearance and contributes to the durability and finish quality of the door. Common materials include:

- Solid Wood Face Panel (Oak, Rubber Wood) For a natural and premium finish, solid wood veneers like oak or rubber wood offer authenticity and warmth, ideal for luxury residential or executive office spaces.

- MDF or HDF (Medium or High Density Fiberboard) These engineered panels are smooth and stable, excellent for painted finishes or laminates, and widely used for both residential and commercial projects.

- Plywood Known for strength and dimensional stability, plywood panels offer a cost-effective yet durable option for a variety of interior spaces.

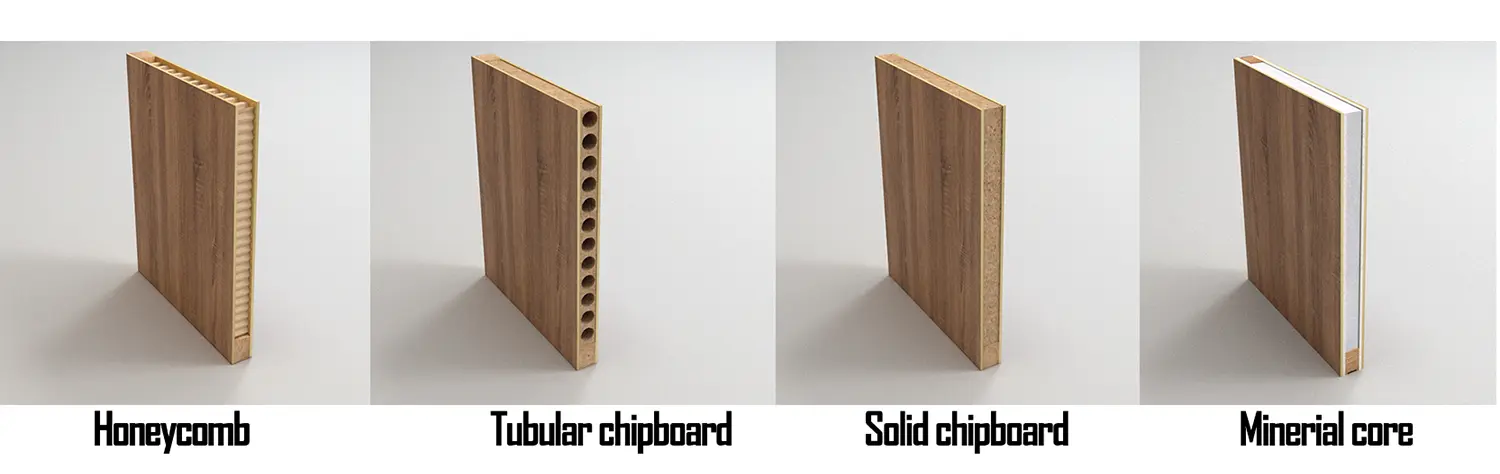

Door Core Options

The core of a flush wood door significantly impacts its strength, acoustic performance, fire resistance, and thermal insulation. You can tailor the core material based on your project needs:

- Honeycomb Paper Core Lightweight and budget-friendly, suitable for standard-use interior doors.

- Tubular Chipboard Core Offers better soundproofing and improved strength with moderate weight.

- Solid Chipboard Core Provides excellent impact resistance and acoustic insulation.

- PU Foam Core Excellent thermal insulation with lightweight construction, suitable for climate-controlled interiors.

- Solid Wood Core High-end, robust solution ideal for areas requiring superior durability and acoustic control.

- Composite Acoustic Core Designed specifically for sound isolation, ideal for offices, schools, and hospitality environments.

- Fireproof Mineral Core Formulated to meet fire safety codes with high fire resistance.

- Honeycomb-like Porous Mineral Core (Homein Recommended) A next-generation material that delivers outstanding fire resistance, sound insulation up to 45 dB, and anti-bending strength, making it ideal for premium applications where high technical performance is required.

Stile and Rail Options

The structural frame inside the flush wood door includes the stiles (vertical parts) and rails (horizontal parts). Options include:

- Solid Hardwood Durable and reliable for high-end applications.

- Solid Softwood Economical and suitable for standard internal doors.

- Laminated Veneer Lumber (LVL) Engineered for stability, reducing warping and offering long-term structural reliability.

By choosing from these combinations, you can build a flush door that precisely meets fire ratings, sound ratings, thermal insulation goals, or design preferences—all while managing costs.

2. Economical Pricing and Efficient Manufacturing

Flush wood doors are widely considered one of the most cost-effective options in the interior door category. This affordability is driven by three major factors:

1. Simple Construction

Unlike panel doors with detailed moldings or glass inserts, flush doors are flat-faced with a basic frame and core structure. This simplicity means less labor and fewer components are involved in the assembly, translating to lower manufacturing costs.

2. Easy Mechanical Production

Flush doors are ideally suited for automated production lines, allowing manufacturers to produce them with minimal manual intervention. As a result, production costs and human error are significantly reduced.

3. Affordable Material Options

Builders can mix and match materials—from basic honeycomb cores to HDF skins—to meet budget constraints without compromising essential functionality. This makes flush doors ideal for large-scale housing projects, schools, hospitals, and commercial buildings where cost control is key.

In short, flush wood doors deliver excellent performance at a competitive price, making them accessible for all types of building projects.

3. Fast Delivery Times for Tight Project Schedules

In today’s fast-paced construction industry, lead times can greatly affect a project's bottom line. With flush doors, you benefit from streamlined production and quick delivery.

Lead Time Advantages

- Melamine Flush wood Doors: Ready in as little as 7 days.

- Painted Flush wood Doors: Require only 14 days for delivery.

This speed is due to their simple design and compatibility with automated fabrication, ensuring that even large orders can be fulfilled quickly and consistently.

Ideal for Time-Sensitive Projects

Flush wood doors are perfect for projects with fixed completion schedules such as hotel renovations, apartment developments, or institutional upgrades. Their rapid delivery allows for fast installation and helps prevent construction delays.

4. Wide Range of Sizes to Fit Any Design

Flush wood interior doors are also valued for their flexibility in sizing, enabling architects and designers to meet unique space and layout demands.

Custom Size Options

- Maximum Width for Swing Doors: Up to 1300 mm

- Maximum Height for Swing Doors: Up to 3000 mm

This generous range allows for oversized single doors, tall architectural entrances, and double-door combinations that can create a seamless and open feel in any interior.

Ideal for Commercial and Institutional Spaces

Schools, hotels, conference halls, and public buildings often require doors that are wider or taller than standard dimensions. Flush wood doors deliver on this requirement without sacrificing structural integrity, especially when combined with durable stile and rail options like LVL or solid hardwood.

5. Multiple Surface Finishes for Aesthetic Versatility

Flush wood interior doors are available in an impressive array of surface finishes, allowing them to seamlessly integrate into any interior design—whether traditional, modern, or industrial.

Available Finishes Include:

- Paint Perfect for clean, minimal interiors and available in virtually any color.

- Veneer Laminate + Paint Offers the elegance of natural wood grains with the added protection of a painted finish.

- Melamine Durable and low-maintenance, with color and texture options including wood, stone, and solid tones.

- High-Pressure Laminate (HPL) Known for high durability, heat resistance, and scratch resistance—ideal for commercial environments.

- PVC Coating Provides a budget-friendly, water-resistant solution with fast production turnaround.

This variety allows designers to tailor the door's appearance to match cabinetry, furniture, wall treatments, or branding requirements.

6. Superior Fire and Sound Performance

Flush wood interior doors aren't just about aesthetics and cost—they're also engineered for high performance in critical areas like fire safety and sound insulation.

Fire Resistance Up to 90 Minutes

Using fire-rated cores such as mineral core or the Homein honeycomb-like porous mineral core, flush doors can achieve up to 90 minutes of certified fire resistance. This makes them suitable for:

- Commercial and high-rise buildings

- Hospital and healthcare facilities

- Educational institutions

- Any space requiring code-compliant fire protection

Sound Insulation Up to 45 dB

For areas where acoustic control is essential—like offices, hotels, recording studios, or shared living spaces—flush wood doors can be built with:

- Composite acoustic cores

- Solid chipboard cores

- Homein porous mineral core

These cores, combined with tight-fitting frames and seals, can achieve up to 45 dB sound reduction, enhancing privacy and comfort.

Flush doors are a quiet powerhouse—literally—bringing together safety, security, and silence.

Conclusion: The Complete Door Solution

From design to performance, flush wood interior doors offer a full package of advantages for modern construction projects. Whether you’re an architect designing luxury hotel suites or a contractor fitting out a budget apartment block, flush doors provide unmatched value, flexibility, and performance.

Key Takeaways:

- Wide selection of face panels, cores, and stiles/rails to match performance or budget

- Simple, cost-effective construction enables competitive pricing

- Fast lead times (7–14 days) support tight project deadlines

- Custom size options up to 1300mm width and 3000mm height

- A range of surface finishes to meet any aesthetic requirement

- Certified performance in fire resistance (up to 90 minutes) and soundproofing (up to 45dB)

Flush wood interior doors are more than just an opening—they are a design and functional asset for any modern interior. Choose them to bring together elegance, efficiency, and engineering precision in one simple yet powerful form.