Tel/wechat/whatsapp : +86 13758983507

Email : info@homeindoor.cn

A flush wood door is a type of door characterized by its smooth and flat surface, without any panels, moldings, or other embellishments; Flush wood doors are known for their sleek and minimalist aesthetic, which makes them a popular choice for both modern and traditional interiors

Choosing a flush wood door offers several advantages that make it a popular choice for both residential and commercial settings. Here are the key reasons:

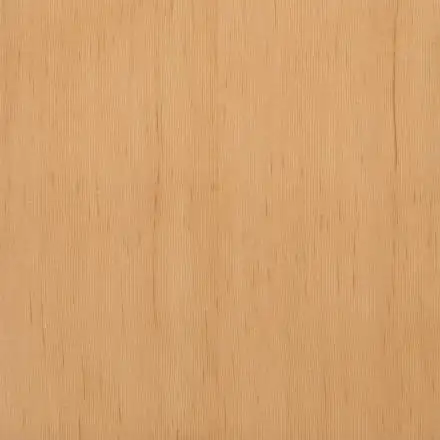

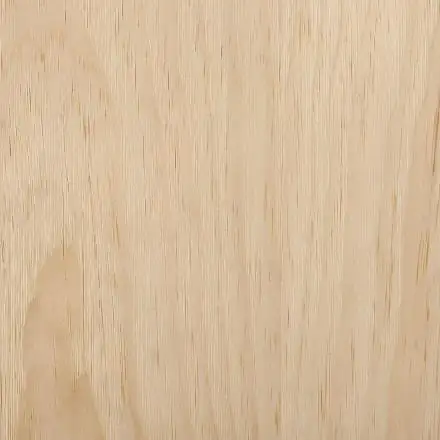

Optional Veneer & Texture

Optional solid color

Standard packaging is the door around the foam corner and edge protection, the surface of a layer of sponge film, and then put into a cardboard box, wrapped with tape; safe packaging can reduce the damage brought about by scratches and collisions in the handling process on site

After the standard packaging, and then put each door into the wooden box, usually the wooden box is made of plywood board or particle board, the bottom of the wooden box has a base can be forklift truck work; Obviously the wooden box packaging increases the cost, but it also brings a lot of benefits, 1 . Convenient for loading and unloading 2. Avoiding damage to the product from collision during international transport, especially for doors with glass.

This packaging is dedicated to pre-hung doors, especially for the North American market, pre-hung doors can greatly save the installation of labor costs and installation time, but pre-hung packaging volume is twice as large as the standard package, reducing the amount of loading quantity to increase the customer's transportation costs

For door and hardware samples, we usually use air freight to save time, we have a long term cooperation with many international express companies, such as DHL, FEDEX; so they give us competitive shipping price and high quality service.

Due to the large volume and weight of the door, usually use sea transportation, our factory is located in Yongkang City, Zhejiang Province, China, the nearest port is the port of Ningbo, followed by the port of Shanghai; from the factory to the port in just 3 hours; sea transportation is very convenient; our factory has more than 20 years of experience in exports; and many shipping companies have long-term cooperation

If foreign customers have containers for consolidation in China, we can transport your door by truck to the customer's designated loading location, such as Shenzhen, Qingdao, Shanghai

We have no minimum order quantity and accept orders in any quantity.Whether you need a single door or material for an entire project, we offer affordable product price and shipping to your country

Any size within the maximum size range can be customized,

Of course,We have a wide range of standard colors to choose from, and we can also produce according to the color card provided by the customer.

Of course, we can ! Our profesional designer can provide detailed design drawings to confirm the specifications and materials before production.

You can also download reference drawing on our website

Of course, we can provide different materials, colors, styles, prices of hardware accessories for customers to choose, where you can one-stop shopping for doors and accessories! Most of our hardware is made in china (chinese brand), We can also supply hardware made by international Top brands (such as Häfele, Dorma), or Equivalent China-made hardware